Theory becomes practice

What does a good quality manual look like? What is the ideal factory layout for battery production? How harmful is methane from urban sewage treatment plants? In the winter semester 2022/23, the semester projects of the MSc Operations Management study programme were once again as interesting as they were diverse. In strong project teams and in close cooperation with their clients, the students developed concepts, models and solutions for current issues. In doing so, they translated theories from their studies into practical applications in a hands-on manner. During the project presentation, all working groups presented their results to the partner companies as well as to the supervising professors and their fellow students.

In order to be sustainably competitive in a fast-moving and global market, innovative approaches are needed to make products visible. Pioneers like Apple or Microsoft stand for a new way of thinking with their marketing strategies and the presentation of their products. But how can a small and medium-sized enterprise (SME) keep up with such strategies and successfully place itself and its products on the market? This is precisely the question that the eight students in the project team tackled. In cooperation with bbg bitbase group GmbH, an innovative market launch concept for the new data protection software kameon PLC was developed with the help of the design thinking approach. The measures contained in the implementation strategy are intended to create the necessary customer base for a successful software rollout and further on the prerequisites for organic customer acquisition and long-term customer loyalty.

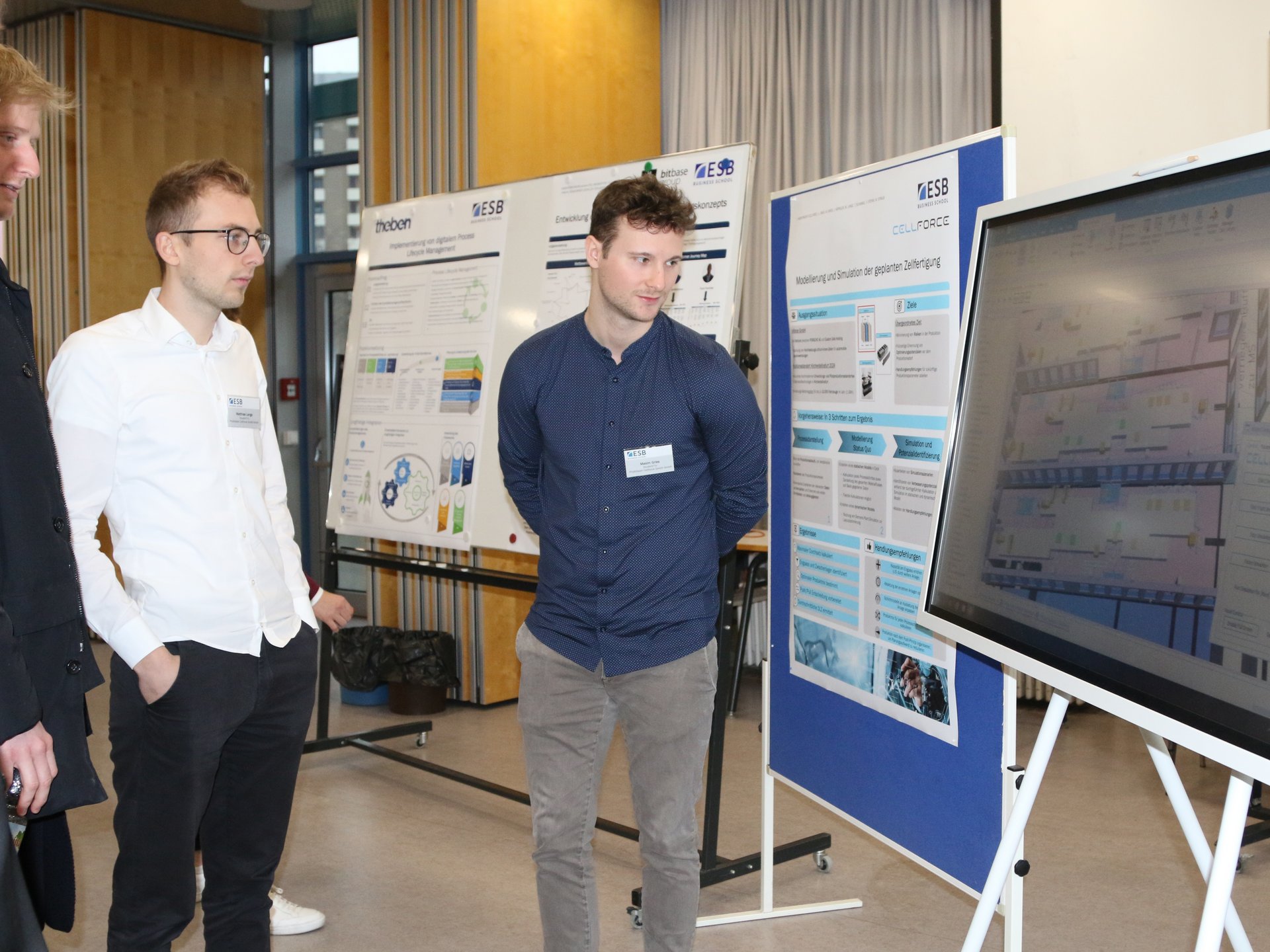

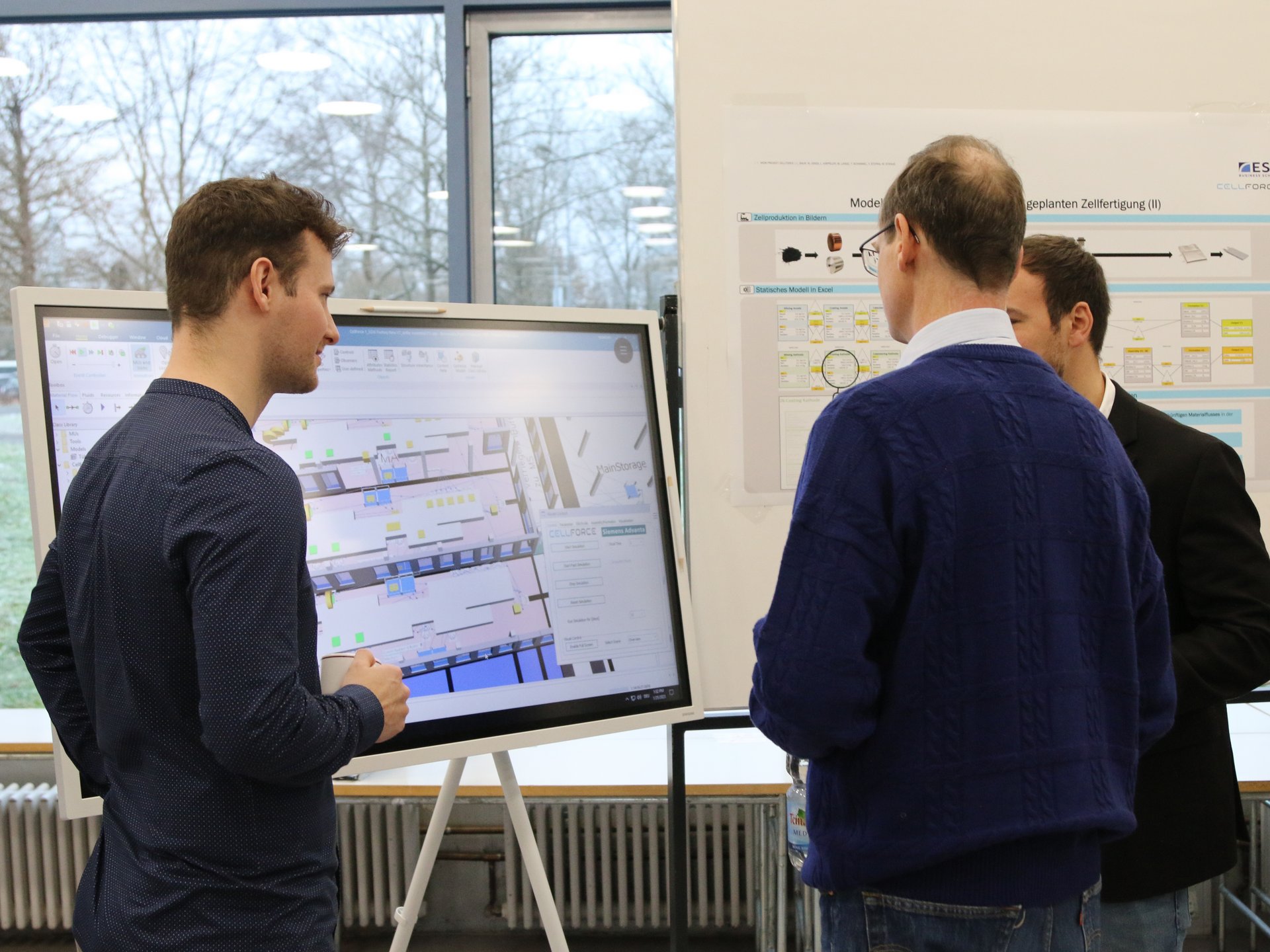

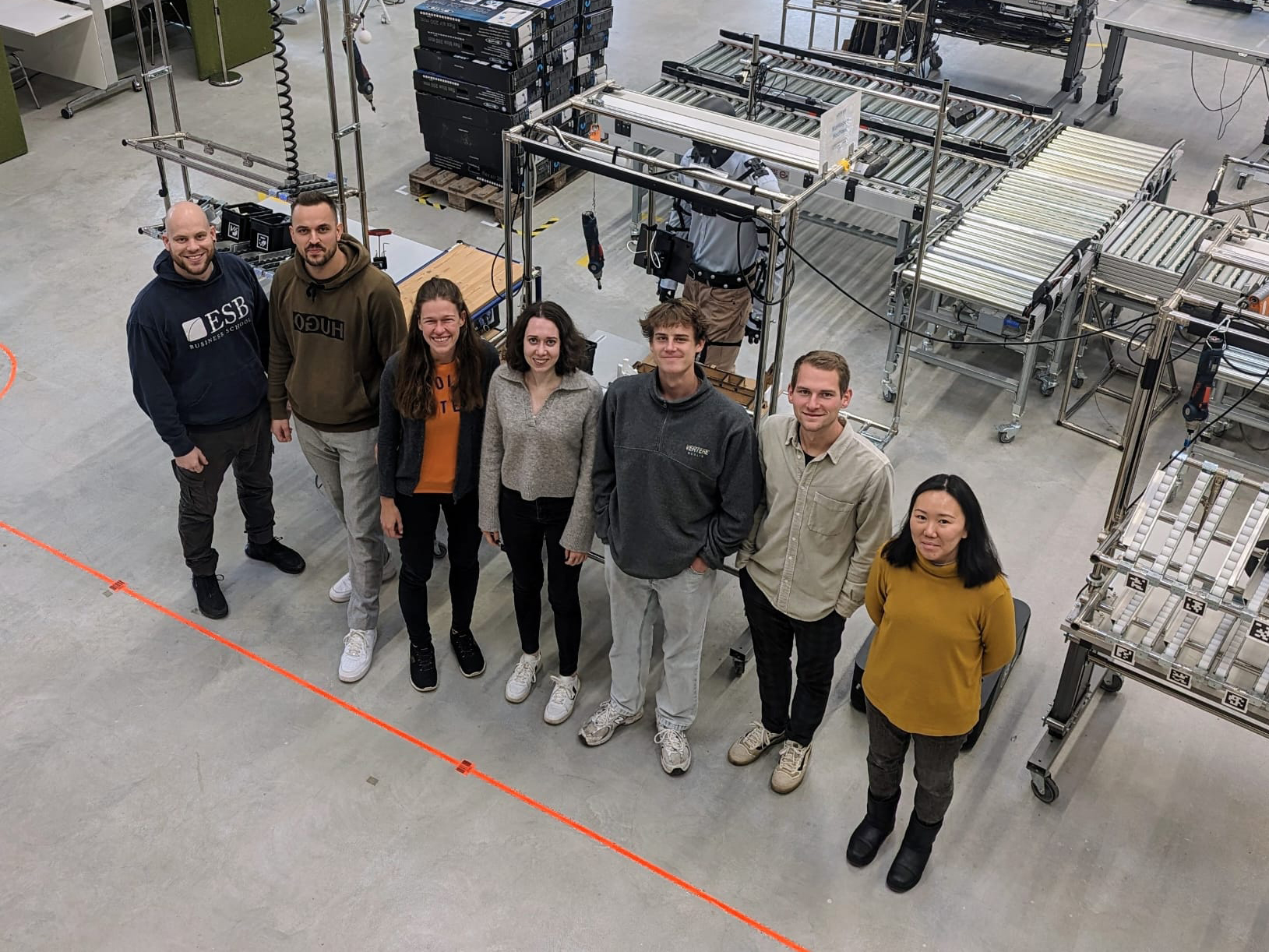

Within the framework of the project, the seven-member team cooperated with the Cellforce Group GmbH. The joint venture of Porsche AG and the battery specialist CUSTOMCELLS will develop and produce high-performance lithium-ion pouch cells for special automotive applications in the Mahden intermunicipal industrial estate in Reutlingen-Nord/Kirchentellinsfurt from 2024. The students created a digital model that depicts the future material flow of battery cell production as realistically as possible. It identifies optimisation potential before the real start of production and provides sound forecasts about the expected output of production. Afterwards, defined test scenarios were simulated in order to detect any bottlenecks or critical processes in production at an early stage. The simulation results obtained can now be used to derive recommendations for action to optimise the factory layout before it is physically built.

The world of work is in a state of constant flux, characterised by technical progress and increasing globalisation. Growing competitive and cost pressures are increasingly reinforcing the impact of technical innovations. How are work sciences and technology/innovation management related? An eight-member project team tackled this question and analysed publications in the two fields together with the Fraunhofer Institute for Industrial Engineering IAO. With the help of a bibliometric analysis, the interfaces between work sciences and technology/innovation management were identified and evaluated with regard to their development over time. A qualitative analysis provided information on the influence of individual subject areas on these interfaces. Thus, the project work provided not only an overview of current publication topics and developments. It also forms a basis for the further orientation of research in the areas of work sciences as well as technology/innovation management.

As part of the project, seven students were assigned by Kärcher Municipal GmbH to investigate whether the introduction of the OTX standard optimises the commissioning process of the S100 sweeper series. The OTX standard (open test sequence exchange) is a uniform, efficient and process-safe standard for test procedures. This allows diagnostic sequences to be executed in various target environments without barriers. In order to take a closer look at the process, a process analysis of vehicle commissioning was first carried out at the plant in Kirchentellinsfurt. Furthermore, the project team fully familiarised itself with the theory of the OTX standard to create an application-related prototype. In the final feasibility study, the technical, organisational and resource-related as well as the economic feasibility were considered and evaluated. The project partners from Kärcher Municipal evaluate the cooperation with the following words: “The students of ESB Business School were always very committed and familiarised themselves with the task in a targeted and structured manner. Thus, a lot of valuable input was generated, which will be very useful for the subsequent project phases.”

Current developments such as urbanisation, population growth and increasing freight traffic volumes pose major challenges for cities. This results in traffic congestion as well as emissions in the form of noise, particulate matter and carbon dioxide that are hazardous to environment and health. In order to be able to present the twin city with initial approaches for improvement, a digital twin was developed to visualise source-sink ratios in city logistics – behind this lies the transportation of orders from the distribution centre to the customers. The basis for the software-supported mapping of various city logistics concepts was formed by the results of the previous project “Design of a City Logistics System” from the previous semester. These were analysed and adapted to a newly defined area of observation in the city centre. In addition to the creation of the digital twin, the recommendations for action derived from it are a further key component of the project. In this process, the benefits and further use of the digital twin for the twin city from Ostwestfalen-Lippe were evaluated.

As a public utility of the city of Reutlingen, urban drainage management is responsible for the operation of the public sewer system and of the sewage treatment plants. Using the municipal target of climate neutrality by 2040, the seven-member project team established the current status of research on the topic of nitrous oxide and methane formation at sewage treatment plants as well as their measurement and impact on the greenhouse effect on the basis of literature and international reference projects.

For example, studies of sewage treatment plants in Austria, Switzerland and Denmark showed that nitrous oxide as well as methane are released via sewage treatment basins. Both substances contribute significantly more to the greenhouse effect than CO².

In cooperation with students from the School of Applied Chemistry, samples were also taken and analysed at the Reutlingen sewage treatment plant. Based on the results, recommendations for action were derived and formulated, which are aimed at minimising emissions to reduce greenhouse gases and a possible energetic use to support the energy supply of the sewage treatment plant.

In cooperation with Theben AG, the project team revised the company’s own quality management manual. The world market leader in time switch technology uses this as a basis for a process-oriented quality management system that supports the company in meeting customer requirements in areas such as smart home, time switches or presence and motion detectors.

The aim of the project was to capture, document and unify relevant processes with the help of the modelling standard BPMN 2.0, using the BIC process lifecycle software. On this basis, a framework was then developed for the permanent integration of a process lifecycle management. “The basis of our success is the competence of our employees and the resulting innovation and quality of our products. We are therefore delighted about the cooperation with ESB Business School”, said a representative of Theben AG.

In cooperation with the scientists at Werk150, the seven students of the project team generated ideas for an intelligent product to present the technology and material cycles of the circular economy. To this end, they developed and produced the first prototypes.

The strategic goal was to further develop Werk150 as a research and training environment for sustainable production and logistics systems. In future, the developed product will be distributed to the students of Reutlingen University. It is equipped with sensors that enable Werk150 to generate user data, with the help of which a diagnostic and service concept is made possible. Sensor data are also made available to the users via a dashboard. The principles of the circular economy were always at the focus of all decision-making, from the selection of materials to the production concepts.