From innovation management to Industry 4.0 - Practice-based excellence in training and research

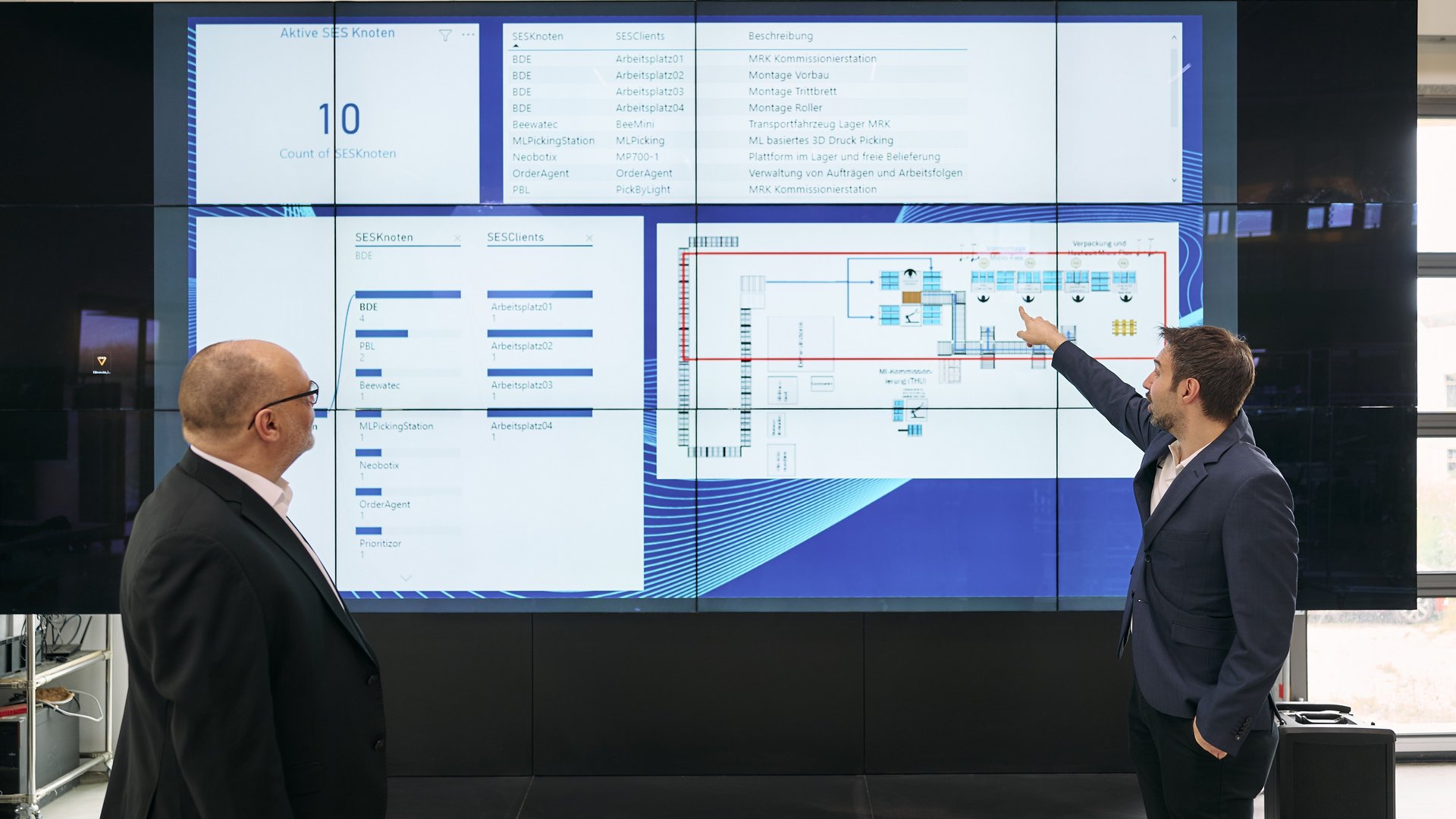

The Training and Research Centre Added Value and Logistics Systems (WLS) is a central facility at ESB Business School. The professors at the Centre deal with current topics from the context of digitisation and Industry 4.0. At Werk150, the ideas become reality.

Main areas of research

Together with partners from science and industry - particularly in close cooperation with the Fraunhofer Institutes for Manufacturing Engineering and Automation and for Industrial Engineering and Organisation - we work on research, joint and contract projects and offer comprehensive technical advice, technology transfer, training and further education on current topics.

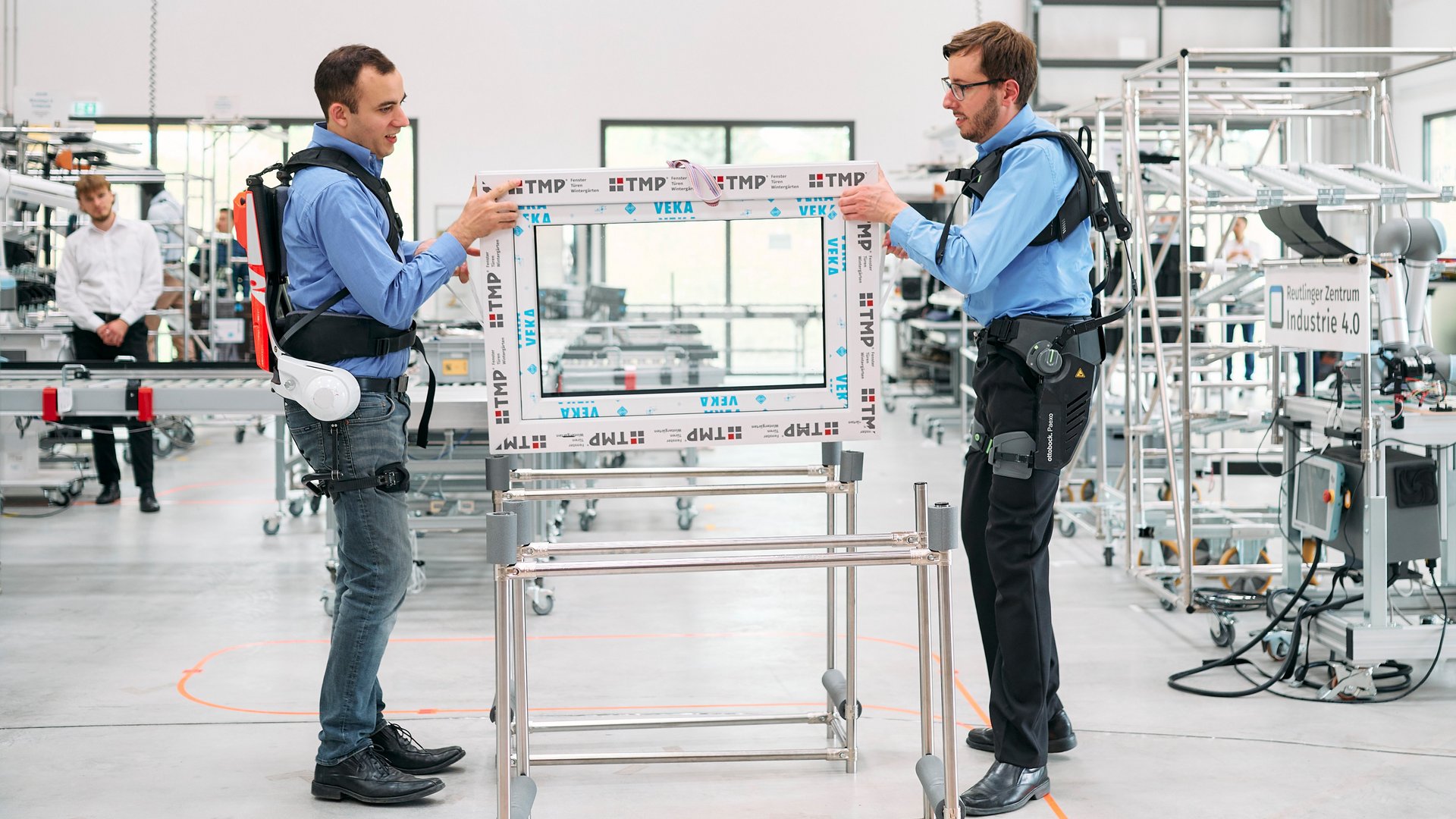

Advanced Industrial Engineering

Automation in Logistics

Communication in Logistics

Technology and Innovation Management

Digital Engineering

Smart Information Logistics

Research activities in the Training and Research Centre Added Value and Logistics Systems

The Training and Research Centre Added Value and Logistics Systems is active in numerous research initiatives and projects, in the field of educational research and research conferences.

Speakers

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/6/csm_Palm_Daniel_2023_06_14_9e3717548b.jpg)

Team

Behind every research project there is a strong team. Find out more about the professors and staff in the research area Value and Logistics.

Become a part of our research team

Permanent positions, research stays, internships - we are constantly looking for strong research reinforcement. For further information, please take a look at our job advertisements.